-

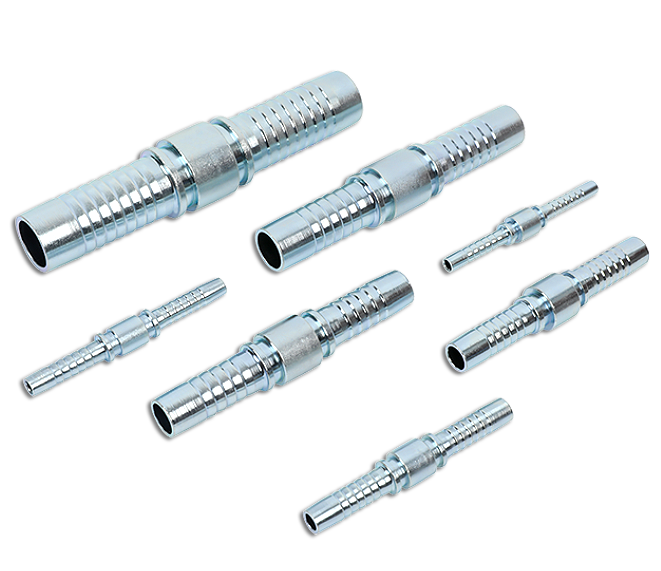

Full Crimp Cap Hydraulic Fittings

Full crimp cap hydraulic fittings are widely used connecting components in hydraulic systems, primarily for connecting hydraulic pipelines. They have the following features: Compact Structure: Full crimp cap hydraulic fittings use an integrated design, which is compact and occupies minimal space, making them easy to install and maintain. Excellent Sealing Performance: Made with high-quality sealing materials, these fittings ensure good sealing performance even in high-pressure environments, preventing hydraulic oil leakage. Easy Installation: The installation process of full crimp cap hydraulic fittings is simple and does not require special tools. Installation can be easily completed by following the correct steps. Wide Application Range: Suitable for various hydraulic systems, such as construction machinery, machine tools, ships, and metallurgical equipment, these fittings can meet the needs of different industries. High Durability: Made from high-strength materials, full crimp cap hydraulic fittings have high pressure resistance and wear resistance, resulting in a long service life. Easy Maintenance: Maintenance of full crimp cap hydraulic fittings is straightforward. Simply check the condition of the seals regularly and replace them as needed.

-

British And American Standard Hydraulic Fittings

British and American standard hydraulic fittings are widely used connecting components in hydraulic systems, primarily for connecting hydraulic pipelines, cylinders, pumps, and other equipment. They have the following features: Standardized Design: These hydraulic fittings adhere to international standards such as SAE and DIN, ensuring compatibility with various hydraulic equipment. High-Quality Materials: Typically made from high-strength steel or aluminum alloy, these fittings offer pressure resistance and corrosion resistance. Compact Structure: The compact design takes up minimal space, making installation and maintenance convenient. Excellent Sealing Performance: Equipped with high-quality sealing rings, these fittings ensure reliable sealing performance in high-pressure environments. Easy Installation: Designed with quick-connect and disconnect features, making on-site installation and replacement straightforward. Wide Application Range: Suitable for various hydraulic systems in fields such as construction machinery, automotive, marine, and aviation industries. Easy Maintenance: Featuring a structure that is easy to disassemble, these fittings facilitate regular inspection and maintenance.

-

Weld-On Hydraulic Fittings

Weld-on hydraulic fittings are an innovative industrial connection solution, highly regarded in modern manufacturing for their performance and reliability. Utilizing advanced welding technology and hydraulic principles, these fittings achieve efficient and stable connections, making them widely used in hydraulic systems, pneumatic systems, lubrication systems, and more. The design of weld-on hydraulic fittings is exceptionally clever, featuring a compact structure and high-strength materials that ensure stability and durability under working conditions. Moreover, these fittings are easy to install and have low maintenance costs, significantly enhancing production efficiency. In terms of environmental protection and energy savings, weld-on hydraulic fittings also excel. Their sealing performance effectively reduces energy waste and environmental pollution. Additionally, the reusability of these fittings contributes to sustainable development. With their innovative design, performance, and environmental benefits, weld-on hydraulic fittings have become a shining star in the field of modern industrial connections. As technology continues to advance, we have every reason to believe that they will play an even more important role in the future.

-

Dual Hydraulic Fittings

Dual hydraulic fittings, also known as double hydraulic connectors or dual-path hydraulic connectors, are essential components widely used in hydraulic systems. They primarily serve to connect two hydraulic lines, enabling functions such as splitting, merging, or switching the flow of hydraulic oil. These fittings are made of high-strength materials, ensuring pressure resistance and sealing performance. Their compact design and simple structure make them easy to install and maintain. Typically, dual hydraulic fittings consist of a connector body, sealing elements, and connecting nuts, and are connected to hydraulic lines via threads or slots. Depending on operational requirements, various interface sizes, pressure ratings, and materials can be selected to meet the demands of different hydraulic systems. In hydraulic systems, dual hydraulic fittings play multiple roles, including pressure control, flow control, and directional control, making them crucial for precise hydraulic system management. They are indispensable in hydraulic systems for construction machinery, metallurgical equipment, marine vessels, aerospace, and other sectors.

PRODUCT CATEGORIES

SEE MORE

-

Customization

We have a strong R&D team,and we can develop a proper production line according to the drawings or samples the customers offered.

-

Quality

We have our own quality inspectors and advanced testing equipment in the industry to meet the testing requirements of various products of customers;

-

Service

We are based on high-quality and high-end markets, and our products meet international standards.

-

Shipment

Our freight transportation is developed here, close to the port, and the export is very convenient.

LATEST PRODUCTS

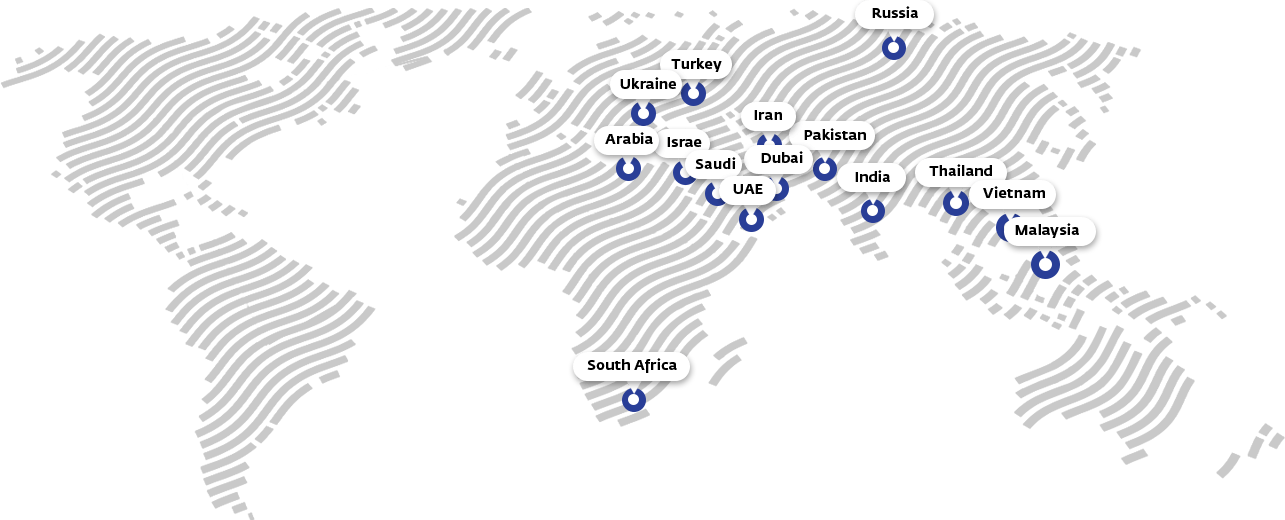

Zhuji E-ching Machinery Co., Ltd.

Zhuji E-ching Machinery Co., Ltd., located in Diankou Town, Zhuji City, Zhejiang Province, the company was established in 2022, is a professional engaged in hydraulic machinery and components development and production of science and technology enterprises, committed to machinery and industry equipment industry innovation, Main hydraulic joints, hydraulic pipe joints and other products. We are a professional

ABOUT US

hydraulic parts manufacturer

, The company covers an area of 25,000 square meters, with office buildings, factory buildings, staff dormitories, etc. The company has more than 100 sets of mechanical processing equipment.Sales Network

English

English русский

русский عربى

عربى